Zoom in

Zoom in

- Name:

HZS180 Concrete Batching Plant

- Minimum Order Quantity:1 Set/Sets

- Supply Ability:15 Set/Sets per Month

- Payment Terms:L/C,T/T

-

Product Description

Quick Details of HZS180 concrete batching plant :

On the basis of combining advantages of various foreign batching plant&stations and advanced technology, HZS180 adopts modular structure design, which maintains convenient installation& removal and safe, comfortable operation, with good mixing effect and high efficiency. Besides, it adpots PLC automatic logical program control and host computer all-time tracking management, with safe and reliable operation and more facilitate maintaining. With fully-closed tower, aggregate conveying system and dedusting system can effectively reduce environmental pollution arising from dust and noise.

Model Number:HZS180 Concrete Batching Plant

Condition:New

Capacity:180m3/h

Main Mixer: JS3000

Power of Main Mixer:110kw

Feeding Mode:Belt conveyor

Mixing Time: 60s

Max Aggregate Size:60/80mm

Discharging Height:3.8m(for customers choice)

Control Mode: Automatic Control System/Central Console Control System

Delivery of HZS180 concrete batching plant:

Packaging Detail: container

Delivery Detail: 12 days

Specifications of stationary concrete batching plant:

HZS180 Concrete batching plant

1.Competitive price and quality

2.Compact structure,reliable performance

3.Warranty:12Month

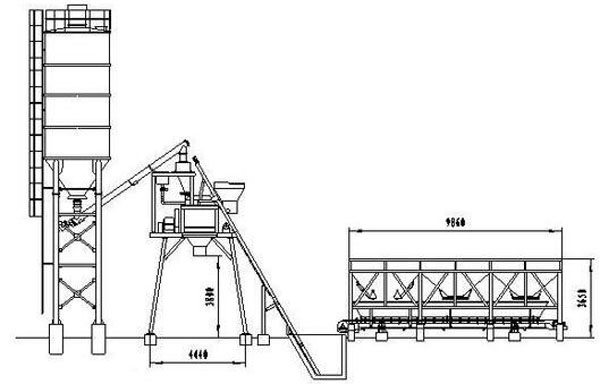

The layout for HZS180 complete concrete batching plant:

Main features of stationary concrete batching plant

1.Adopt combined structure and modular unit, convenient to install and remove;

2.Mixing and aggregate lifting system adopt JS3000 double-shaft compulsory concrete mixer which offers high quality and efficient mixing;

3.Aggregate batching system adopts PLD4800 concrete batcher which offers efficient and accurate measurement;

4.Powder lot is electronic measured, highly accurate dosing;

5.Water is flow-metering, simple and practical, highly accurate dosing.

|

Main technical data of stationary concrete batching plant |

|

|

Type |

HZS180 concrete batching plant |

|

Productivity in theory |

180m³/h |

|

Mixer |

JS3000 |

|

Total power |

205KW |

|

Maximum aggregate diameter |

80mm |

|

Aggregate feeding method |

Conveyor belt |

|

Aggregate bins volume |

4x18m³ |

|

Aggregate weighing |

2x4000kg ±2% |

|

Cement weighing |

1800kg ±1% |

|

Fly-ash weighing |

800kg ±1% |

|

Water weighing |

800kg ±1% |

|

Additive weighing |

50kg ±1% |

|

Overall dimension(during operating) (LXWXH) |

58.5mX7mX12.9m |

|

|

|

|

Discharging height |

3.8m |

|

Total weight |

77T |

|

Control |

Fully automatic central control |

|

Cement silo(optional) |

Required on clients' demand |

|

Cement screw(optional) |

Each cement silo equipped with one φ325 screw |