Zoom in

Zoom in

- Name:

HZS90 Concrete Batching Plant

- Minimum Order Quantity:1 Set/Sets

- Supply Ability:15 Set/Sets per Month

- Payment Terms:L/C,T/T

-

Product Description

HZS90 concrete batching plant has the compact and reasonable structure, small occupation area, and adopts L type layout and unique feeding type, which adopts belt conveyor in great inclined to feed. The ready mixed concrete plant owns good mixing effect and high efficiency, its control system adopts PLC automatic logical program, host computer all-time tracking management, with safe and trustable operation and more facilitating maintenance.

Model Number: HZS90 concrete batching plant

1,Condition:New

2,Capacity:90m3/h

3,Main Mixer:JS1500

4,Power of Main Mixer:44kw

5,Feeding Mode:Belt conveyor

6,Mixing Time:60s

7,Max Aggregate Size:60/80mm

8,Discharging Height:

9,3.8m(for customers choice)

10,Control Mode:Automatic Control System/Central Console Control System

11,Aggregate Weighing Precision:2%

12,Cement Weighing Precision:1%

Packaging & Delivery of batch plant:

Packaging Detail:container

Delivery Detail:12 days

Specifications of HZS90 Concrete batching plant :

1.Competitive price and quality

2.Compact structure,reliable performance

3.Warranty:12 Month

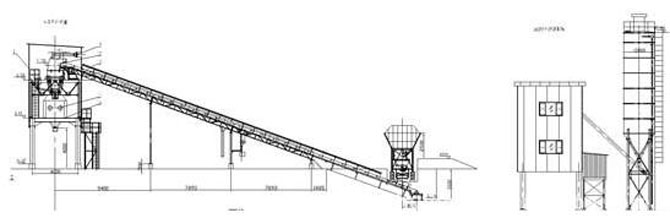

The layout for HZS90 complete concrete batching plant

Main features of HZS90 concrete batching plant:

1. Adopt combined structure and modular unit, convenient to install and remove;

2. Mixing and aggregate lifting system adopt JS1500 double-shaft compulsory concrete mixer which offers high quality and efficient mixing;

3. Aggregate batching system adopts PLD2400 concrete batcher which offers efficient and accurate measurement;

4. Powder lot is electronic measured, highly accurate dosing;

5. Water is flow-metering, simple and practical, highly accurate dosing.

|

Main technical data of HZS90 concrete batching plant |

|

|

Type |

HZS90 concrete batching plant |

|

Productivity in theory |

90m3/h |

|

Mixer |

JS1500 |

|

Total power |

140Kw |

|

Maximum aggregate diameter |

80mm |

|

Aggregate feeding method |

flat conveyor |

|

Aggregate bins volume |

4X13 m³ |

|

Aggregate metering |

6000Kg ±2% |

|

Cement metering |

1000Kg ±1% |

|

Fly ash metering |

500Kg ±1% |

|

Water metering |

500Kg ±1% |

|

Additive metering |

50Kg ±1% |

|

Overall dimension(during operating) (LXWXH) |

35.6m×18.3m×11.8m |

|

|

|

|

Discharging height |

3.8m |

|

Total weight |

64T |

|

Control |

Fully automatic central control |

|

Cement silo(optional) |

according to the user demand, quantity and size can choose |

|

Cement screw(optional) |

each powder silo match one φ219 orφ273 screw |