Zoom in

Zoom in

- Name:

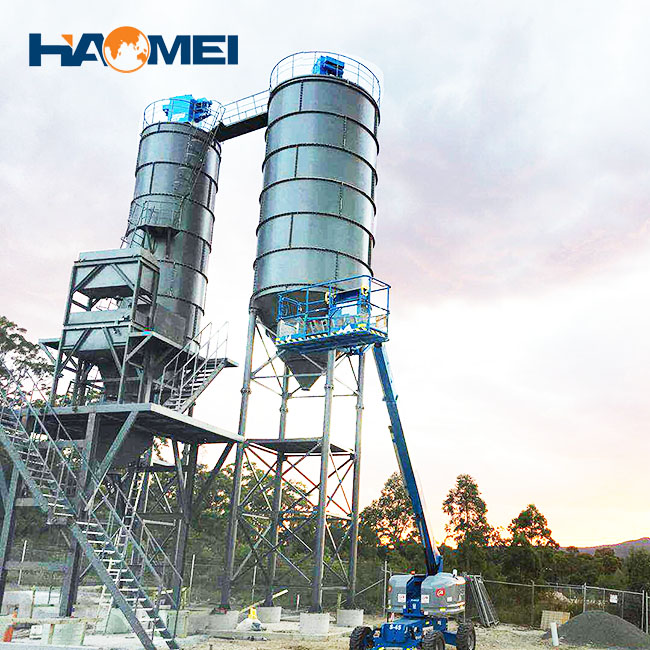

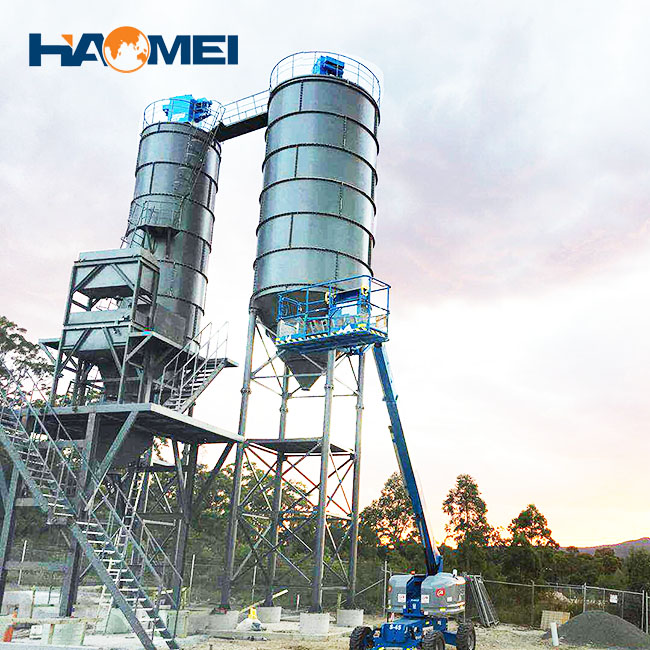

Dry mix concrete batching plant

- Minimum Order Quantity:1 Set/Sets

- Supply Ability:15 Set/Sets per Month

- Payment Terms:L/C,T/T

-

Product Description

The dry mix concrete batching plant is composed of a aggregate batching machine, a cement supply system, a water supply system, a cement weighing system, a water weighing system, a control system, etc. It does not have a concrete mixer, and the aggregates and powders are weighed and mixed, then directly discharged into the concrete mixer truck with water in its tank. It is mainly used in areas with a large area and sparsely populated areas to avoid segregation of wet concrete due to long-distance and long-term non-stop movement in the mixer truck, which will deteriorate the quality of the concrete.

Specifications of dry mix concrete batching plant

|

Type |

HZS25 |

HZS35 |

HZS50 |

HZS75 |

|

|

Theoretical production capacity(m3/h) |

25 |

35 |

50 |

75 |

|

|

Aggregate Bin volume(m3) |

3.2 |

7.3 |

8.3 |

12 |

|

|

Weighing Accuracy |

Aggregate (KG) |

1500Kg ±2% |

2200Kg ±2% |

3000Kg ±2% |

4500Kg ±2% |

|

Cement(KG) |

300Kg ±1% |

450Kg ±1% |

600Kg ±1% |

1500Kg ±1% |

|

|

Fly ash(KG) |

|

|

400Kg ±1% |

600Kg ±1% |

|

|

Water (KG) |

200Kg ±1% |

200Kg ±1% |

400Kg ±1% |

600Kg ±1% |

|

|

Additive(KG) |

|

30Kg ±1% |

50Kg ±1% |

50Kg ±1% |

|

|

Total power(KW) |

45Kw |

60Kw |

115Kw |

110KW |

|

|

Discharging height(M) |

3.8 m |

3.8 m |

3.8 m |

3.8m |

|

|

Gross weight(T) |

7.7 |

15 |

40 |

50 |

|

|

Type |

HZS60 |

HZS90 |

HZS120 |

HZS180 |

HZS240 |

||

|

Theoretical production(m3/h) |

60 |

90 |

120 |

180 |

240 |

||

|

Aggregate Bin volume(m3) |

8.38 |

12 |

20 |

30 |

40 |

||

|

Belt conveying Capacity(t/h) |

300 |

450 |

550 |

650 |

900 |

||

|

Weighing Accuracy |

Aggregate (KG) |

3000Kg ±2% |

3000Kg ±2% |

2200Kg ±2% |

3000Kg ±2% |

4200Kg ±2% |

|

|

Cement(KG) |

1500Kg ±1% |

1500Kg ±1% |

1200Kg ±1% |

1800Kg ±1% |

2200Kg ±1% |

||

|

Fly ash(KG) |

600Kg ±1% |

900Kg ±1% |

400Kg ±1% |

500Kg ±1% |

800Kg ±1% |

||

|

Water (KG) |

600Kg ±1% |

600Kg ±1% |

500Kg ±1% |

800Kg ±1% |

1000Kg ±1% |

||

|

Additive(KG) |

50Kg ±1% |

50Kg ±1% |

50Kg ±1% |

80Kg ±1% |

80Kg ±1% |

||

|

Total power(KW) |

|

120Kw |

165Kw |

130Kw |

170KW |

220KW |

|

| Discharging height(M) | 3.8m | 4.1m | 4.1m | 4.1m | 4.1m | ||

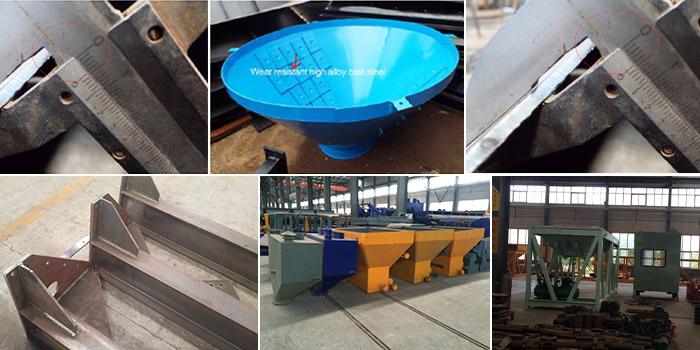

Features of dry mix concrete batching plants

1. Very suitable for areas with large areas and sparsely populated areas.

2. A dry mix concrete batch plant need no concrete mixer, and has low investment and high return.

3. High efficiency and energy saving. No need to stir, save time and electricity.

4. Computer control, the entire production process can be displayed intuitively on the screen.

5. Precise batching system (aggregate, cement, water, additives, etc.)

6. The belt feeding system is continuous and efficient.

A dry-mix concrete batching plant has both disadvantages and advantages:

The advantage is: because of the special working mode, such a mixing plant is suitable for the task of providing concrete to a remote transportation site. The mixing process is carried out in the mixer truck, which saves the construction period and can also slow down the initial setting time of the ready-mixed concrete. In this way the quality of the concrete can be ensured after long-distance delivery. A dry mix concrete batch plant is especially suitable for small engineering projects requiring lower about the quality of concrete.

The disadvantage is that although the cost of a dry concrete mixing station itself is low, it is not suitable for mass production. First, the work efficiency cannot keep up, because the effective mixing volume of a mixer truck is too small to meet mass production. Second, if too many mixer trucks are invested, the cost will increase and the economic benefits will be greatly reduced. Therefore, a dry mix concrete mixing plant can only be used as a good supplementary equipment rather than a main concrete batching plant.