HZS Series Of Continuous Concrete Batching Plant Basic Configuration

Writer:Admin Time:16/09/09Mixing Host of continuous concrete batching plant

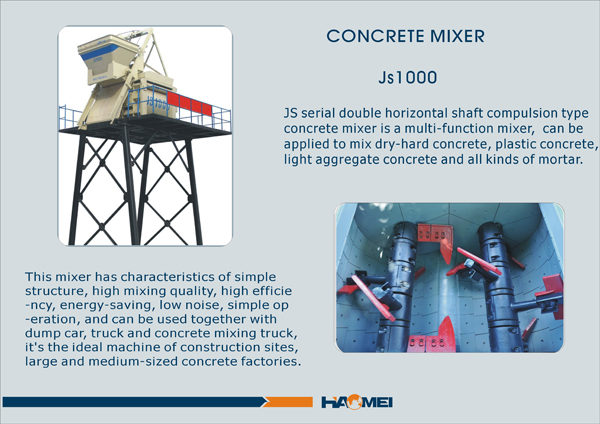

According to the mixing methods fell into forced mixer and mixer.The mainstream of the forced mixer is used batching plant at home and abroad, it can stir liquid, half dry hard and harsh, and other concrete.Since the fall type main stirring liquidity concrete mixing console, now rarely used in the station.Forced mixer in the form of the structure spindle planetary mixer, single shaft mixer with double shaft mixer, notably the dual-axial mixing machine comprehensive performance is best.

Material Weighing System concrete mxing plant China

Material weighing system, mainly divided into aggregate weighing, powder weighing and liquid weighing three parts. Under normal circumstances, 20m3 / aggregate (sand, stone) with a balance, cement and fly ash with a bar, water and liquid admixtures were weighed, and then put the liquid admixture into the water, said the bucket pre-mixed. In the 50m3 / a variety of materials used in an independent weighing mode, all weighing are used electronic scales and computer control. Aggregate weighing 2% accuracy, cement, powder, water and admixture weighing accuracy of 1%.

Material conveying system

By the conveying of aggregate, powder conveying and liquid transportation of three parts.Aggregate conveying: at present there are hopper conveying and automatic concrete batching plant aggregate conveying belt conveyor in two ways.The advantage of bucket conveyor is cover an area of an area small, simple structure.Belt conveyor transmission distance is large, the advantages of high efficiency, low failure rate.Belt conveyor is mainly used in aggregate for temporary storage of mixing station, and can improve the productivity of mixing station.Powder conveying: concrete available powder is mainly cement, fly ash and mineral powder.

Material Storage System

Concrete materials available for storage are basically the same, there are aggregate open-air pile (also city large-scale commercial concrete mixing station with closed silo); powder with a fully enclosed steel silos for storage; admixture with steel container storage.

Control system

Mixing station control system is a complete set of equipment of central nervous system.According to user requirements and the size of the mixing station control system and have different functions and different preparation.In general, the construction site of the available small simple mixing station control system, and large mixing station system is relatively complicated.