Which components of batch plant need regular inspection

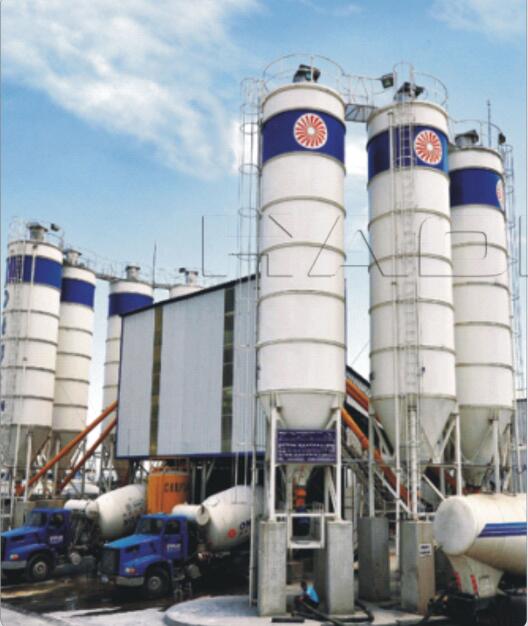

Writer:Admin Time:17/10/31Which components of batch plant need regular inspection?After the concrete batching plants is put into production, not only the daily operation and production are needed, but also the timely cleaning and maintenance is very important. In order to ensure profits and benefits, regular maintenance and inspection are very important, especially for commercial concrete mixing plant.

1. The pneumatic sealing, oil cup, oil level and drainage;Check the sensor is normal;

2. The belt conveyor head and scraper adjustment, the adjustment of the sweeper in belt;

3. aggregate conveying equipment: check the belt running and the interface; check the movement of the cylinder and the opening and closing of Doumen;

4. check belt roller running situation, check motor running, temperature rise is normal;

5. regularly check the drive drum oil level;

6. power supply line and lighting situation;

7. check whether the driving roller locating screw and the refueling screw are loose;

8. the work of the sprinkler is abnormal, the transfer station hopper wear degree and adhesive cleaning, lubrication points oiling.

9. motor and pump operation;

10. leakage of water pipe valve; check the water level of pump room, should be added immediately when it is insufficient;

11. check the batch plant level of water tank at any time, insufficient timely supplement.