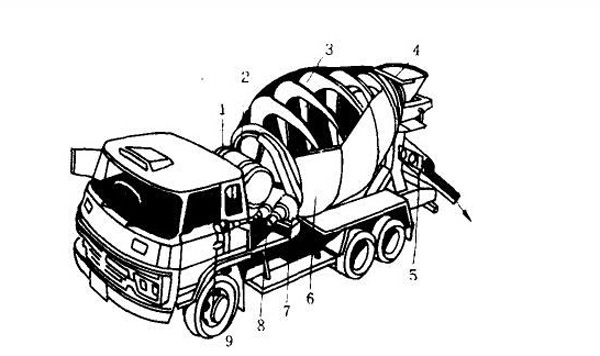

The Overall Structure Of Concrete Mixer Truck

Writer:Admin Time:16/05/16Below is the concrete mixer truck .Mixing drum main bearing of the front bearing seat is installed on the front of main bearing can automatically adjust the heart.Backend support two roller in the bracket, bracket on the auxiliary frame before and after.After mixing barrel by hopper above, below after installation has a discharge chute.Mixing barrel is equipped with two spiral blade.Driving force of the mixing barrel is usually taken from the car engine, after taking power, hydraulic pump, hydraulic motor, chain and sprocket to churn.Concrete mixer is equipped with a constant speed refers to the mixing drum on truck chassis, uniformly discharge spiral blade and hydraulic power systems and other special equipment for mixing concrete tank cars.

- Previous:The Load Test Of Concrete Mixing Plant...

- Next:Concrete Batching Plants Problems In Daily Use...